Carlsen 130 Screw Sump

- Description

- Construction

- Screw Conveyor

- Motor and Gearbox

- Electrical Controls

- Fittings and Connections

- Standard Features

- Connection Features

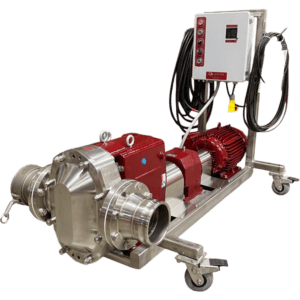

This portable sump for the Carlsen 130 sits under the discharge of the destemmer-crusher or receiving hopper. The start/stop on the screw sump will coordinate with the must pump control so that starting and stopping the sump will also start and stop the must pump. These portable sumps for the Carlsen 130 help your winemaking operation by fitting seamlessly into your current system.

Construction

Construction

- 1-1/2″ square tube stainless steel frame

- 12 gauge stainless steel body

- Stainless steel casters with brakes

Screw Conveyor

Screw Conveyor

- 9″ diameter stainless steel conveyor screw

- Seal-welded on both sides of screw

- UHMW flight edging

Motor and Gearbox

Motor and Gearbox

- 1 hp TEFC motor

- 60 rpm Gearbox

Electrical Controls

Electrical Controls

- Variable frequency drive

- Waterproof enclosure and switches

- Forward/Reverse switch

- Panel mounted speed control

- Pigtail for utilizing remote stop/start devices

- 50′ of power cord (the electrical plug is to be supplied by the customer)

- 10′ of cord for connection to the must pump control for stop/start devices

Fittings and Connections

Fittings and Connections

- 4″ male camlock on sump snout

- 4″ female camlock x 3″ Triclamp fitting with clamp and gasket (connects sump to pump)

- All fittings are stainless steel

Standard Features

Standard Features

- Designed for the Carlsen 130

- Domestic Gearbox and Motor

- Stainless Steel Construction

- Variable Frequency Drive

- NEMA 4X Enclosure

- Variable Speed

- Forward and Reverse

- Two-Year Warranty

Connection Features

Connection Features

- Automatic Control of the Pump’s Stop/Start Function

- Easy Camloc Connection